Superbolt® Torquenuts

Get a QuoteIn Stock - Discounted Pricing - Truckload PricingCall: 713.681.5811

The Superbolt® Torquenut is the most widely used, multi-jackbolt mechanical tensioner. The Torquenut is a bolt or stud tensioner that can fit into the space requirements of a heavy hex nut. The standard Torquenut, suitable for use at temperatures up to 600°F (315°C), can generate pre-loads compatible with Grade 8 or Grade 5 bolts or A193-B7 studs and is available in thread sizes from ¾" to 6". Special Torquenuts have been supplied to pre-stress precipitation hardening steels up to a 160,000psi level. Other specials have been made for 12" press columns.

The Superbolt® Torquenut is the most widely used, multi-jackbolt mechanical tensioner. The Torquenut is a bolt or stud tensioner that can fit into the space requirements of a heavy hex nut. The standard Torquenut, suitable for use at temperatures up to 600°F (315°C), can generate pre-loads compatible with Grade 8 or Grade 5 bolts or A193-B7 studs and is available in thread sizes from ¾" to 6". Special Torquenuts have been supplied to pre-stress precipitation hardening steels up to a 160,000psi level. Other specials have been made for 12" press columns.

Superbolt® Full Overview Brochure

Superbolt® Dimension List Torque Guidelines

Superbolt® Installation Guidelines

Holding Power

When properly torqued, Superbolt® Torquenuts will not come loose. Pre-stressed nuts and bolts remain tight on vibrating or pulsating equipment and on constantly reversing loads. Our products lose only 3% of their initial pre-load after 1,000,000 cycles when stressed to 98% of the initial pre-load. Even less is lost when loaded to a lesser degree. Tests are available upon request.

Simple Concept

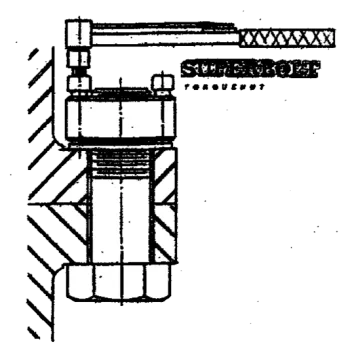

A Superbolt® Torquenut is threaded on to a mating member bolt, a long anchor bolt or the end of a threaded shaft. The main thread is used for positioning only. Once the Superbolt® Torquenut is properly positioned, actual tensioning is accomplished by tightening the jackbolts located around the main thread.

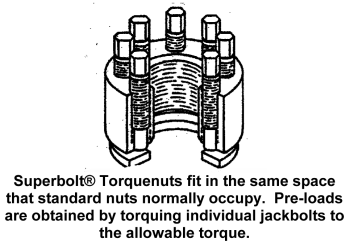

Superbolt® Torquenuts fit in the same space that standard nuts normally occupy. Pre-loads are obtained by torquing individual jackbolts to the allowable torque.

Economical

Superbolt® Torquenut is a simple, relatively low cost mechanical tensioning device. By comparison, hydraulic tensioning devices are very expensive and can generate only a fraction of the pre-load produced by our product.

Time Savings

The relative ease of mounting and removal can reduce application time and simplify maintenance procedures. Superbolt® reduces downtime caused by fasteners that vibrate loose.

No Special Tools Needed

Superbolt® Torquenuts require only a small automobile-size torque wrench to properly tension hard-to-reach nuts, such as the 2" nuts found on some gas compressors between the cylinders (in steeples). They also are ideal where you can’t fit a pipe cheater.

Superbolt Torquenuts used with Rowan Anchor Bolt Assemblies R-193 Series Full Data Sheet

| part#/bolt diameter | jack bolt torque (ft lbs) | preload (lbs) |

| MT-150-8 | 42 | 84,300 |

| MT-150-8 | 35 | 70,250 |

| MT-150-8 | 28 | 56,200 |

| MT-150-8 | 21 | 42,150 |

| MT-162-8 | 49 | 98,400 |

| MT-162-8 | 46 | 92,400 |

| MT-162-8 | 42 | 84,000 |

| MT-162-8 | 38 | 75,600 |

| MT-175-8 | 57 | 99,000 |

| MT-175-8 | 46 | 79,200 |

| MT-175-8 | 34 | 59,400 |

| MT-175-8 | 23 | 39,600 |

| MT-100-8 | 27 | 48,600 |

| MT-100-8 | 24 | 44,080 |

| MT-100-8 | 21 | 38,570 |

| MT-100-8 | 18 | 33,060 |

| MT-112-8 | 27 | 48,600 |

| MT-112-8 | 24 | 43,680 |

| MT-112-8 | 20 | 36,400 |

| MT-112-8 | 16 | 29,120 |

| MT-125-8 | 27 | 64,800 |

| MT-125-8 | 23 | 55,740 |

| MT-125-8 | 19 | 46,450 |

| MT-125-8 | 15 | 37,160 |

| MT-137-8 | 49 | 73,800 |

| MT-137-8 | 46 | 69,300 |

| MT-137-8 | 38 | 57,750 |

| MT-137-8 | 31 | 46,200 |

| MT-187-8 | 90 | 138,000 |

| MT-187-8 | 75 | 115,000 |

| MT-187-8 | 60 | 92,000 |

| MT-187-8 | 45 | 69,000 |

| MT-200-8 | 86 | 132,500 |

| MT-200-8 | 69 | 106,000 |

| MT-200-8 | 52 | 79,500 |

| MT-200-8 | 34 | 53,000 |

Home > Products > Superbolt® Torquenuts

Request a Quote

Call 713.681.5811 to request an immediate quote or you can request a quote by filling out the form below. We usually get back to you within the same business day.