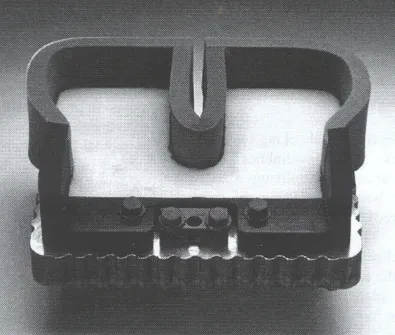

Rowan Tri-Brid™ Improved Universal Engine Support System - Tri-Brid Adjustable Epoxy Chock

Get a QuoteIn Stock - Discounted Pricing - Truckload PricingCall: 713.681.5811

The Tri-Brid™ Epoxy Chock System is a universal machine support system, meaning it will fit a machine base that is machined flat and true, or in combination with a pourable epoxy chock can be used with worn fretted surfaces, or "waffle" bottoms.

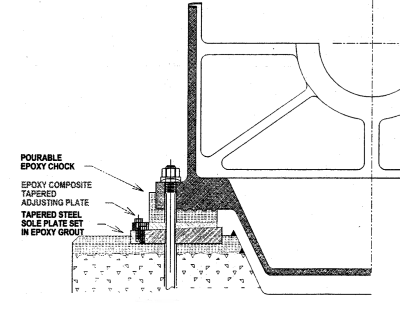

The top plate is made of a strong epoxy composite and precision machined to match the steel sole plate. Infinite adjustment over the range of ±.028 inches is accomplished by precision tapered surfaces. Both the epoxy chock material (when used), as well as the Tri-Brid™ composite material provides heat insulation to reduce thermal humping of the machine being supported.

ADVANTAGES:

- WILL FIT ANY MODEL ENGINE FRAME

- NO MACHINING OF BASE REQUIRED FITS

- WAFFLE BOTTOM OR FRETTED STEEL

- SHIMLESS ADJUSTABILITY +/- .026" PROVEN

- IN OVER 12 YEARS OF SERVICE

- EXCELLENT HEAT INSULATION

- STEEL SOLE PLATE WITH GROUT LOCK PROFILE

- 2 BUILT IN JACK SCREWS FOR ALIGNMENT

Recommended as a machinery support system for large:

- Reciprocating gas engine

- Engine-generators

- Gas turbines

- Paper machines

- Marine engines

- Coupled machinery trains

- Motor driven equipment

FEATURES

- Independent vertical adjustment at each anchor bolt

- Excellent heat barrier – can be used up to 300° F.

- Vertical adjustment capability of .056" (+.028")

- Resistant to lubricating oils and cooling water

- Design provides a 2" air gap under machine base for better cooling

- Unique steel sole plate edge detail enhances bond to epoxy grout.

- Allows for thermal growth of the machine

- Excellent vibration absorption combined with precision alignment

- Can be used with non-machined or badly worn machinery bases (even a cast waffle bottom)

Home > Products > Tri-Brid Adjustable Epoxy Chock

Request a Quote

Call 713.681.5811 to request an immediate quote or you can request a quote by filling out the form below. We usually get back to you within the same business day.