Anchor Bolt Repair Kit

Get a QuoteIn Stock - Discounted Pricing - Truckload PricingCall: 713.681.5811

Make a suitable repair to minimize reoccurrence and downtime using Rowan Anchor Bolt Repair Kit.

You will need:

4140 Hex coupling nut with optional flange (to increase anchoring when repairing lower strength broken anchor bolts). Self-Aligning, Double Spherical Washer, and Rowan Resin 427 Epoxy Grout.

How to Repair an Anchor Bolt

Anchor bolts do break from time to time. The ability to make a quick repair is essential to minimizing downtime. Two very important considerations are:

Anchor bolts do break from time to time. The ability to make a quick repair is essential to minimizing downtime. Two very important considerations are:

- Make a suitable anchor bolt repair with the minimum of lost time and disruption of the equipment.

- Make a repair that is better than the original installation so recurrence is unlikely.

The question is often asked, "Why do anchor bolts break?" Usually, it is one of two reasons. The first is an improperly designed original installation which could be anything from a wrong specification of the steel to the improper physical sizing i.e., length, depth of embedment, amount of free stretch, or preload applied. The second is improper maintenance of the anchor bolt; such as not keeping the nut tight. More bolts break from being under-tightened, than over-tightened. It is extremely important that the proper preload be applied to the anchor bolt before equipment start up, and that the preload be maintained during the life of the installation. Nuts can loosen in service and that means a loss of the preload. Critical anchor bolts should have load monitors to detect such a loss of preload, or a scheduled periodic check of the tightness using a torque wrench, so any loss of torque (or preload) can be corrected before a broken bolt or damage to the equipment occurs.

Torque wrenches are not very accurate, not because of the wrench, but because of field conditions, such as lubrication of the threads, etc., but they are much better than nothing. Much has been written on the subject and further information can be obtained from the reference noted below.

Repair Procedures

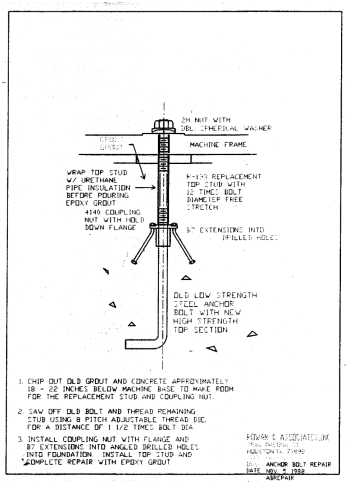

The most effective way to repair an anchor bolt is to cut off the old bolt low enough below the equipment base, so the replacement top section length will be at least 10 to 12 bolt diameters. Do not consider welding, as the steel in many anchor bolts does not weld satisfactorily. Mechanical threading with a coupling nut is the only sure repair. The length of the coupling nut should provide for vertical adjustment since making an exact cut in a hole chipped out underneath a machine is difficult.

A further note on the coupling nut is that if the old anchor bolt stub is of doubtful integrity, the coupling nut should incorporate a hold-down flange with holes so additional anchoring can be added. Steel all-threads can then be added and tied into angle drilled holes in the concrete. Using this system, an old, low strength steel bottom section can be upgraded in load carrying capacity to match a replacement top section of high strength 4140 steel.

Home > Products > Anchor Bolt Repair Kit

Request a Quote

Call 713.681.5811 to request an immediate quote or you can request a quote by filling out the form below. We usually get back to you within the same business day.