Grouting Problems - Machinery Foundations

After 65 plus years of experience in precision equipment grouting with cementitious and epoxy grouts, a variety of problems have been seen. Certain problems crop up repeatedly, indicating that better education and written instructions should be directed toward the most frequently encountered problems.

Types of Grouting Problems

Grouting problems can be split into two categories: those that occur during the grout installation or placement and those that appear after the grout has cured. We will talk about the second group in this issue, as listed below:

- Cracking

- Poor bond/edges lifting

- Initial cold alignment changes

- Hot alignment changes

- Long-term alignment changes

Since the real measure of an equipment grout is how it performs over time, we'll discuss the effect of these long-term problems.

Please keep in mind the real purpose of grout. Does it maintain the proper original alignment over the life of the machine, say for 20 years? Are unbalanced forces contained or absorbed into the foundation without excessive equipment movement? Do the anchor bolts maintain their specified preload, or does creep allow bolt tension to relax? Is machinery wear held to a minimum?

Since the reason for buying a premium machinery grout, such as a high quality epoxy grout, is to have positive responses to questions like these, let's examine those problem areas listed above and see how they affect long-term grout performance.

Cracking

Complaints about cracking of epoxy grouts probably equal all of the others put together, so a look at why they occur, what can be done to minimize them, and if cracks affect the grout performance, is in order. Are they an indicator of grout failure or are they just a cosmetic problem?

Cracks; both vertical cracks, from the grout surface down to the concrete interface where they usually stop, and horizontal cracks in the concrete or at the concrete and grout interface, are found regularly. These are the result of stress that develops in the grout during curing or from the higher coefficient of expansion of epoxy grouts, compared to the coefficient for concrete or steel. Environmental conditions during grout placement, such as ambient temperature, material temperatures and humidity levels, play a major role in how much stress is locked into the grout as it cures. These stresses can later be released by cracking, because of the higher coefficient of expansion of epoxy materials.

Since epoxies have a higher coefficient of expansion, they will grow or shrink faster than steel or concrete during heating and cooling cycles.

Equally as important is how the epoxy grout is formulated. As a rule of thumb, the more rigid a grout is, the better it maintains the precision alignment of the machine and the more likely it is to crack. Epoxy grouts that are formulated to the point of being almost flexible so they won't crack may later creep or cold flow enough to allow alignment changes.

A grout can also be so rigid that it causes enough stress on the concrete interface so that bond and alignment are lost. Somewhere between the two extremes is the ideal formulation that minimizes the bad properties. Epoxy grouts have performed well for over 63 years, indicating that proper formulations are currently available commercially.

Do cracks themselves indicate that there is a potential problem? Usually not. Even the best formulations available today can crack, but this does not mean the equipment alignment has changed or will change or that the load-carrying ability of the grout has been diminished.

Cracks are usually in the nonload-bearing shoulder areas and rarely extend under the equipment support surfaces. Even so, they should be repaired so that oil or water cannot enter and cause a problem later on. Cracks in epoxy grouts are repairable, and this should be done before the crack surface is contaminated by oil.

Cracking in epoxy grouts can be minimized by adding all of the aggregate required by the manufacturer and by proper installation techniques. The following will help minimize cracking: shading from direct sunlight, moderate environmental temperatures, designing the installation for minimum thickness consistent with flow distance under the machine, reducing the shoulder widths, rounding sharp edges, and properly spaced expansion joints.

Expansion Joints*

Since all factors cannot be controlled or changed, the most valuable tool available for reducing cracking is to have ample expansion joints in the grout cap. These can even be decided on in the field at the last minute, when the experienced installer sees some of the following factors existing but which he cannot change. This is not to say that expansion joints should not be part of the foundation drawing details, but they also can be added, as needed, just prior to grouting.

An example of when this might be wise is if sharp corners are found on rails, sole plates, jack screw landing plates, or the equipment base itself (if in contact with the grout). It's pretty hard to change the under-radiused corner of a plate once

it is in and the alignment completed, but a sharp corner can be blunted with "duct seal" or an expansion joint added at the end of a sole plate or rail or in a large shoulder.

But even if a crack does develop despite the precautions taken, it usually means that a stress that built up in the grout has now been relieved. The crack may not show up for several months, perhaps after a cold snap, but even so, as long as there is still proper alignment, sealing the cracks is all that is required.

This will not be true if the crack in the grout is the result of a crack in the concrete foundation block.* Likewise, if the crack is a result of a loose base plate or an anchor bolt problem, then the support system problem needs to be corrected, in addition to repairing the crack.

Poor Bond

Since epoxy grout bonds well to concrete, poor bond is not nearly as prevalent a problem as cracking. Usually, lack of bond is the result of a failure to chip the laitance completely off of the top of the block. The block should be chipped to expose the large aggregate, breaking some in the process.

Poor bond can result from contamination of the concrete by oil, dirt, and, of course with epoxy grouts, water. Dry concrete is a must. Moisture can travel up to the surface from within the concrete if the block is not yet fully cured, or it can come from an improperly sealed anchor bolt sleeve that is full of water. The heavier epoxy grout will displace the water in the sleeve and flood several square feet of adjacent concrete in the process.

If the block has become wet from rain, it needs to be allowed to thoroughly dry. Simply blowing the top surface dry will invite a poor bond if moisture below the surface rises by capillary action, much the same as can happen with "green," undercured concrete. Sometimes what appears to be poor bond of the epoxy grout to the concrete interface occurs on the vertical edge of the concrete block if the grout cap extends to the edge.

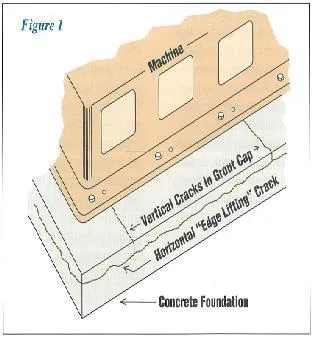

Particularly with new concrete blocks that haven't developed their full tensile strength before grouting, a horizontal crack can develop near the grout interface, usually ¼" to ½" below in the concrete. (See Figure 1).

Particularly with new concrete blocks that haven't developed their full tensile strength before grouting, a horizontal crack can develop near the grout interface, usually ¼" to ½" below in the concrete. (See Figure 1).

This is the result of a tensile load applied to the concrete by the grout as it cures or thermal movement of the grout cap relative to the grout's higher coefficient of expansion. In this case, the grout is usually bonded to the concrete, but the pull exceeds the tensile strength of the concrete below.

Unless there is a vertical crack in association with the horizontal crack, horizontal cracks, as a rule, start in the concrete and travel upward at a slight angle until they intercept the grout interface and stop. Usually, this will be 2" to 4" from the edge of the block. The limit of this edge failure can be determined by sounding with a hammer.

In the vicinity of a vertical crack, the horizontal crack in the concrete can follow the path of the vertical crack toward the equipment but will stop where the compressive load on the grout from the equipment and bolt preload keeps the bond line in compression. Occasionally, the surface of the grout along the vertical crack will be displaced relative to the other side, because of the disbonding along the crack line. Proper sealing of the vertical crack with a suitable, pumpable epoxy injection grout should stop progression of the horizontal crack. These cracks are more of a concern from a cosmetic point of view, since they rarely extend under the equipment.

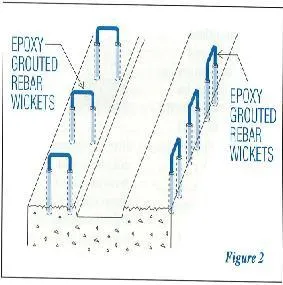

While the expansion joints used to control vertical cracking also help with the horizontal or edge lifting types of cracks, chipping the edge of the concrete block 30° to the vertical removes the weak shear plane where the cracks start. In addition, the use of rebar wickets or dowels on 6" to 10" centers along the edge gives extra holding to resist the forces that can cause a horizontal crack, particularly on large corner shoulders. (See Figure 2). A diagonal expansion joint across the corner, which will divide the grout mass, thus reducing the magnitude of the forces, is another effective way of controlling this problem.

While the expansion joints used to control vertical cracking also help with the horizontal or edge lifting types of cracks, chipping the edge of the concrete block 30° to the vertical removes the weak shear plane where the cracks start. In addition, the use of rebar wickets or dowels on 6" to 10" centers along the edge gives extra holding to resist the forces that can cause a horizontal crack, particularly on large corner shoulders. (See Figure 2). A diagonal expansion joint across the corner, which will divide the grout mass, thus reducing the magnitude of the forces, is another effective way of controlling this problem.

Initial Alignment Changes

This problem has the potential of causing damage to the machine being supported. If the grout, or epoxy chock, as the case may be, allows the equipment base to deflect vertically when full torque is put on the anchor bolt prior to start up, the machine can be pulled out of alignment.

Properly cured, the epoxy grout or chock should ideally not allow any pull-down as measured by a dial indicator on the engine base during anchor bolt torquing. In the real world, there usually is some pull-down from 0" up to .0015" as the anchor bolt is fully tightened and the sole plates, chocks or grout bed seat themselves.

If not properly formu-lated, the grout material itself can contribute to this. Instances of .014" pull-down have been reported from the field! Most specifications, or good operating practices, will limit the acceptable pull-down at each anchor bolt to less than .004" , with the goal of less than .002" .

A very hot overcatalyzed epoxy mixture can cause excessive curing temperatures, particularly in 2 component materials. Such materials expand from the reaction heat during their fluid or plastic stages and then set. Subsequent cooling probably causes the mass to contract, thus providing some slack that will show up as a high pull-down number in the .006" to .008" range during bolt torquing.

While pull-down sounds bad, it takes quite a bit to influence the crank web deflection readings, so good cold alignment after bolt torquing is the rule rather than the exception. It is still a good idea, though, to do a cold alignment check after torquing, and before start up.

Hot Alignment Changes

Even with good cold alignment readings, it is important to know what the hot alignment numbers are after the equipment has run for a week or two and reached heat equilibrium. Crankshafts tend to "bow" upward as heat in the foundation increases. Much more is known today about thermal growth patterns of modern equipment, and sometimes deliberate cold misalignment may be called for so that when the unit is running at operating temperatures, acceptable hot deflection readings will result.

While the instances of poor hot alignment problems are low, it is extremely important to take steps to minimize a potential problem that could lead to a crankshaft failure. It's a recognition of the thermal changes that can occur that has led people away from full bed epoxy grouting of frames over 15 ft. in length, even though for years many frames have been successfully full bed grouted.

Managing Hot Alignment Changes

Over 36 years ago, a trend of using metal sole plates or rails in conjunction with 1" steel chocks started. The air space under the machine created by the 1" chock reduced the temperature of the machine base and the heat going into the block. The steel chock provided a means of changing alignment without regrouting if a good hot alignment was not achieved.

This was followed by the use of 1" thick, poured-in- place epoxy chocks that created the same air gap as a steel chock but allowed less heat to go down into the block. Heat going into the concrete block foundation, more in the center than the ends which can lose heat, is a major contributor to the thermal humping of crank-shafts. Epoxy chocks are insulators, so they block some of the heat that would be transmitted through a steel chock, but do not lend themselves to easy realignment. Epoxy chocks simply are not as easy to knock out and replace, as it would seem, and more than one may have to be removed and repoured since most epoxy chocks pull down some during bolt torquing.

Repouring epoxy chocks also requires allowing for up to 48 hrs. of down-time while the chock cures.

Some steel sole plate manufacturers have further refined their products to go to 2" split steel chocks with stainless steel shims, thus increasing the air gap and providing an easier way to correct alignment than with a single steel chock. Such systems allow realignment at one anchor bolt to be achieved with a couple of hours of down time, considerably faster than a poured-in-place epoxy chock that takes time to cure.

The latest development to help with the problem of correcting alignment is the adjustable epoxy chocking system (Rowan Tri-Chock™) that combines the several advantages of epoxy chocks with the adjustability feature of 2" split shimmable steel chocks.

The epoxy chock com-ponent of this design allows its use where steel chocks have failed by fretting the machine base or if the machine has a "waffle" bottom. Adjustments can be made in increments of .001 inch vertically over a total range of ± .026 inches. Because of the advances that have been made in installation techniques, materials and support systems, correcting poor hot alignment is no longer the difficult problem it once was. With today's adjustable technology, both new or retrofitted machines can be run with near perfect hot alignment.

In the past, equipment operators had to settle for an alignment which, while near the manufacturer's out-of-tolerance limit, couldn't be changed without chipping out the epoxy or steel chocks and starting over. In such cases, even the slightest bearing wear could cause enough alignment change to go beyond the acceptable crank web tolerances.

It just makes better sense to start initially with near perfect hot crank web alignment, and today's newer technology of adjustable epoxy chocks makes this possible.

Problems with Deep Epoxy Pours

While long term alignment changes were not as prevalent 30 years ago, the more recent usage of epoxy grouts in thicknesses of over 5" for foundation rebuilding purposes is causing a new set of problems. It is not unusual to see epoxy grouts used to rebuild foundations with 14"- to 18"-deep pours.

Epoxy grouts do not match the replaced concrete in modulus of elasticity or creep resistance, and such deep pours can contribute to accelerated machine alignment changes. Such deep pours of epoxy grout can allow differential vertical deflection of the machine over time, so the bad effects of this practice are just now being fully realized.

With the advent of new polymer modified concrete materials (such as R-Crete Plus™) the use of epoxy grout to rebuild a foundation no longer makes sense. Not only is a polymer modified concrete cheaper than epoxy grout, it matches more closely the original concrete so the original rebar or an improved rebar design can be utilized.

Polymer concretes with their higher modulus of elasticity can transfer tensile loads to the necessary steel reinforcing. Lower modulus

epoxy grouts do not transfer tensile loads as well. Polymer modified concrete repair materials, such as R-Crete Plus™, offer advantages over the original concrete as they will bond to old, clean concrete and the polymer used helps block penetration of fluids, such as oil, into the repaired area. Equally as important, only 24 hours are required to develop the necessary compressive strength, and it is cured well enough in 24 hours to accept an epoxy grout cap!

While long-term alignment changes have come into focus in recent years, they can be greatly minimized by the use of a polymer modified concrete instead of a deep pour of epoxy grout.

Home > Newsletters > Grouting Problems - Machinery Foundations